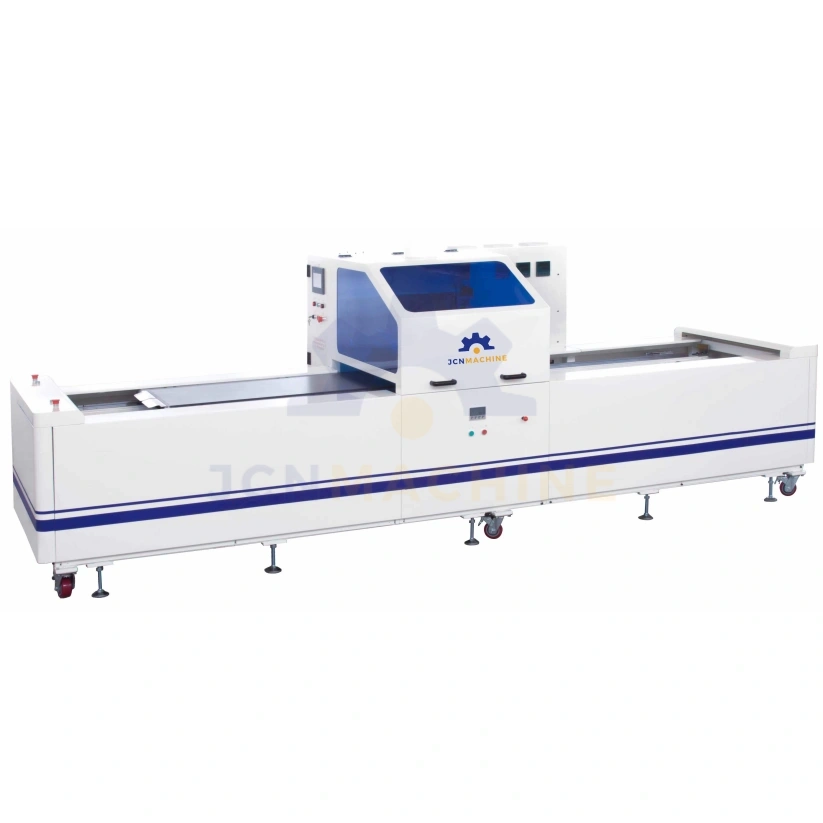

QC550 Coating Machine: Best Future of Automotive Interior Production

Introduction In today’s automobile manufacturing industry, the quality and aesthetics of interior materials have become the focus of consumers, and with it comes higher requirements for the production process of interior materials by manufacturers. The production of interior materials requires not only a high degree of precision, but also cost control while ensuring quality. Although traditional manual or semi-automatic production methods can complete basic gluing and processing, they have obvious shortcomings in production efficiency, material waste, and labor costs. In order to meet these challenges, high-precision coating machines have become a key tool for solutions, especially when dealing with automotive interior materials such as leather, sponges, and non-woven fabrics. Through precise coating processes, the QC550 coating machine can not only effectively reduce material waste, but also greatly improve production efficiency and ensure uniform and consistent surface

Packaging automation: Improving furniture production efficiency

Introduction In today’s highly competitive manufacturing industry, packaging automation seems to have become commonplace, and more and more companies have decided to adopt it after seeing its benefits. This is not only to make production more efficient, but also because in recent years, with the faster pace of cities, people are constantly pursuing faster speeds, whether it is takeout or express delivery, and the same is true for production. The increasing pursuit of speed by consumption has led to the need for factories to save time little by little at many details to ultimately achieve the pursuit of speed. What followed was the days of manual packaging, and now more and more companies have realized that they must rely on automation to keep up with this fast-paced market. Many people think that packaging automation is only for improving efficiency, but this is not the case. Its appearance is to make companies more flexible in the face of market changes. Imagine that mar

Automation in Manufacturing: Boosting Efficiency and Process Optimization

INTRODUCTION The history of the Industrial Revolution has been like a long and exciting marathon, with each leap making the pace of manufacturing more robust. Beginning with the first industrial revolution in the 18th century, we used water and steam power to break the shackles of manual labor and give productivity a powerful boost. Factories then, like freshly wound clocks, began to run at a whole new speed. Immediately following this, the Second Industrial Revolution turned the dream of mass production into a reality through the popularization and application of electricity. Electricity not only provided a constant source of energy for machines, but also realized the goal of “machines making machines,” and factories were like gas pedals, with production lines speeding up again. In the 20th century, the third industrial revolution, electronic equipment and information technology (IT) is widely used, as if for the industrial manufacturing “intelligent” switch. From then on, pro

Automatic Equipment: 2024 Trends and Flexibility in Manufacturing

1.Introduction Imagine: In a dynamic modern factory, the complex tasks that once relied on human operations are now being completed by automated equipment with amazing speed and precision. The production workshop is no longer a scene of bustling people, but an efficient collaborative space dominated by smart devices. This transformation not only redefines the boundaries of productivity, but also drives the entire industry forward. Automated production equipment has surpassed the traditional assembly line model and become the cornerstone of corporate strategic flexibility. According to the latest data, the global automation equipment market has reached 1.2 trillion US dollars in 2023, and it is expected to increase to 1.5 trillion US dollars by 2024 (Source: Statista). This remarkable growth not only reflects the increase in market demand, but also reveals a deeper trend: in today’s complex and changing global market, automatic equipment provides companies with unprecedent