PUR Hot Melt Adhesives: Benefits & Applications

1. The Rise of PUR Hot Melt Adhesives PUR hot melts first hit the scene in Switzerland during the 1980s, and let’s just say, they’ve stuck around for a reason. These adhesives aren’t just your average glue—they’re like the reliable friend you want in your corner. PUR hot melts started making waves in industries like furniture and automotive in Europe and quickly crossed the pond to America. Today, they’re a mainstay in various industries that appreciate their “stick-to-itiveness” and versatility. Take, for instance, the RTM1300A automated cutting and laminating line. This system can automatically cut and apply materials to surfaces in furniture production, making life easier for manufacturers by reducing labor and boosting productivity. With five units and a PUR glue machine, this setup shows just how valuable PUR technology is across the board. 2. The Unique Chemistry of PUR Hot Melts Now, PUR hot melts aren’t your run-of-the-mill adhesives. They’re in a league of their own because t

What is a veneer machine?

Veneer equipment—including the machines that produce finished veneer—is critical to enhancing the appearance and value of wood products. Equipment like cutters, gluers, splicers and shears allow us to produce high quality veneers and laminates for high-end furniture and other applications. As woodworking professionals, we are always looking for ways to enhance the beauty and value of our products. One of the most effective tools for achieving a superior finish are veneer machines. But what exactly is a veneer machine, and how can it revolutionize our craft? Understanding this important piece of equipment can significantly improve the quality of our work and customer satisfaction. Explore the world of Veneer Machines Problem: We are often faced with the challenge of improving the aesthetics of our wood products without significantly increasing costs. Obsession: Without the right equipment, adding luxury finishes can be time-consuming and inefficient, potentially making us less competit

Adhesive Lamination Machines for Efficient Furniture Manufacturing

Discover how adhesive lamination machines boost efficiency and customization in furniture manufacturing, shaping the future of automated production.

QC550 Coating Machine: Best Future of Automotive Interior Production

Introduction In today’s automobile manufacturing industry, the quality and aesthetics of interior materials have become the focus of consumers, and with it comes higher requirements for the production process of interior materials by manufacturers. The production of interior materials requires not only a high degree of precision, but also cost control while ensuring quality. Although traditional manual or semi-automatic production methods can complete basic gluing and processing, they have obvious shortcomings in production efficiency, material waste, and labor costs. In order to meet these challenges, high-precision coating machines have become a key tool for solutions, especially when dealing with automotive interior materials such as leather, sponges, and non-woven fabrics. Through precise coating processes, the QC550 coating machine can not only effectively reduce material waste, but also greatly improve production efficiency and ensure uniform and consistent surface

The Future of Production: Manufacturing Technology Transformation

Introduction: The background and need for technological change in the manufacturing industry Manufacturing, as the “backbone” of the global economy, has developed and evolved over centuries. Since the first industrial revolution in the 18th century, manufacturing has been the “perpetual motion machine” that drives economic growth. But as time goes by, those traditional manufacturing processes are like old cars, although still able to run, but in the face of the fast lane of the modern market, it seems incompetent, which is also the trend of the times, and gradually the second industrial revolution, the “third industrial revolution” appeared. Traditional manufacturing processes often rely on manpower and experience, like the 20th century screws on the grain need to be manually using a lathe to do. In the early stages of industrialization, this approach did allow productivity to “get off to a flying start”, but today, with the complexity of market demand, the traditional p

Advanced PUR Hot Melt Adhesive Technology in Furniture Industry

INTRODUCTION PUR hot melt adhesive (also known as reactive hot melt adhesive, reactive polyurethane, or RPU adhesive) has become a crucial adhesive in the modern competitive manufacturing industry, just like screws in the manufacturing industry, which is unobtrusive but crucial, and it has been emphasized by the furniture and other industries due to its excellent performance in a wide range of situations and conditions. And according to a 2023 report by MarketsandMarkets, the global PUR hot melt adhesive market is expected to reach $15 billion by 2025, growing at a CAGR of more than 7%. Behind this phenomenal market growth are the irreplaceable advantages of PUR hot melt adhesive in terms of adhesion, durability and efficiency. But many people will also ask, just hear you say it is very good, this data does not tell us anything, there are many growth industries, but it is popular because of what properties in the end? That’s what this article will be about. The adh

PUR Adhesive: Revolutionizing veneer Technology

1. Introduction Imagine gazing at a piece of beautifully crafted furniture, the smooth surface and impeccable texture are all amazing. You may wonder how these materials are given such an outstanding appearance? The secret behind all this is actually hidden in an invisible “magic” – PUR adhesive. This little hero widely used in the manufacturing industry is quietly changing the landscape of the entire industry. PUR adhesive, also known as PUR HOT-MELT GLUE, is not just an ordinary glue. It is more like a “super glue” in the industry. With its excellent bonding performance and excellent adaptability, it has successfully overcome the challenges faced by traditional adhesives. Unlike old-school glues that can only work under specific conditions, pur adhesive not only provides strong adhesion at lower temperatures, but also forms a stable chemical cross-linking structure during the curing process. This cross-linking is like a “handshake between m

Packaging automation: Improving furniture production efficiency

Introduction In today’s highly competitive manufacturing industry, packaging automation seems to have become commonplace, and more and more companies have decided to adopt it after seeing its benefits. This is not only to make production more efficient, but also because in recent years, with the faster pace of cities, people are constantly pursuing faster speeds, whether it is takeout or express delivery, and the same is true for production. The increasing pursuit of speed by consumption has led to the need for factories to save time little by little at many details to ultimately achieve the pursuit of speed. What followed was the days of manual packaging, and now more and more companies have realized that they must rely on automation to keep up with this fast-paced market. Many people think that packaging automation is only for improving efficiency, but this is not the case. Its appearance is to make companies more flexible in the face of market changes. Imagine that mar

Manufacturing Engineering & Technology: Leading Green Manufacturing

Introduction Global trends in green manufacturing technologies Now, green manufacturing engineering & technology has become the “number one star” in the global industry, and is eagerly pursued by governments and enterprises around the world. Not only because it helps combat climate change, but also because it caters to the needs of a growing number of environmentally conscious consumers. After all, what company doesn’t want to make a difference in the field of environmental protection? As global environmental regulations become increasingly stringent, corporate investment in green manufacturing technologies is also growing rapidly. For companies that want to cut costs and reduce pollution, this technology is a boon. According to a report by Allied Market Research, the size of the global green manufacturing technology market in 2020 was approximately US$87.2 billion. It is expected that this market will grow to US$155.5 billion by 2030, with a compound annual gro

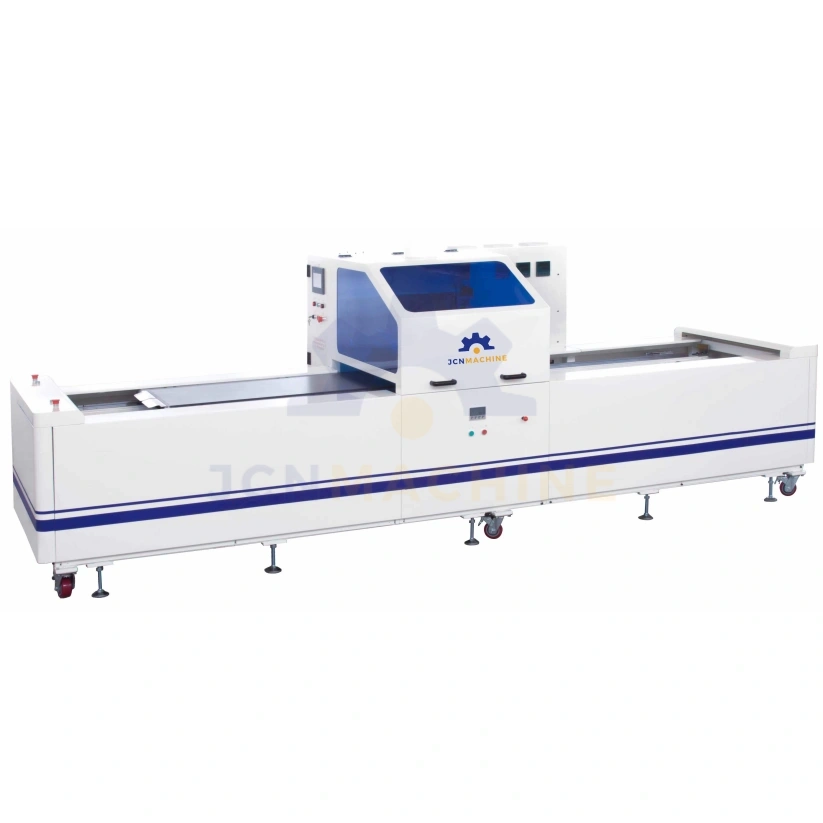

Honeycomb Laminating Technology: A Game Changer in Manufacturing

1. Background introduction In some future museum, you may see a sign that reads, “Shown here is a past production method, a process that was once widely used by companies but was eventually replaced by more efficient technology-for example, Honeycomb Laminating Technology.” Yes, with the rapid growth of manufacturing, sheet metal production has entered a new era. For the furniture and construction industries, panels are more than just materials; they are a symbol of quality and efficiency. However, traditional production methods often struggle to meet both requirements. Like weaving a net by hand, each stitch requires great patience and precision, but efficiency never keeps pace with demand. 2. Introduction to RTM1300A Honeycomb Laminating Line At this moment, the RTM1300A Honeycomb Laminating Line comes on stage. This machine is like a Swiss Army Knife, tailor-made for the modern furniture manufacturing industry. It consists of seven stand-alone machines and one PUR glue suppl