Introduction

In today’s highly competitive manufacturing industry, packaging automation seems to have become commonplace, and more and more companies have decided to adopt it after seeing its benefits. This is not only to make production more efficient, but also because in recent years, with the faster pace of cities, people are constantly pursuing faster speeds, whether it is takeout or express delivery, and the same is true for production. The increasing pursuit of speed by consumption has led to the need for factories to save time little by little at many details to ultimately achieve the pursuit of speed. What followed was the days of manual packaging, and now more and more companies have realized that they must rely on automation to keep up with this fast-paced market.

Many people think that packaging automation is only for improving efficiency, but this is not the case. Its appearance is to make companies more flexible in the face of market changes. Imagine that market demand suddenly changes and the order volume suddenly surges. In this case, automated packaging equipment can quickly adjust the production speed to avoid the slow speed of manual packaging and delay the delivery of goods. Moreover, these automated systems can help companies respond to these changes more quickly through intelligent control, and truly adjust the production rhythm at any time.

On the other hand, there is another pain point for enterprises. With the continuous increase in labor costs, especially in developed countries, enterprises are paying more and more attention to how to reduce costs through technical means. Airbus is a representative of this. In recent years, Airbus has continuously used new technical means to improve engine efficiency and reduce fuselage weight, ultimately achieving the goal of improving fuel efficiency. The same is true for automated packaging systems, which is one of the best solutions for enterprises to improve efficiency. It can not only greatly reduce the dependence of enterprises on manual labor, but also reduce the possibility of errors. Although this sentence is the last thing all workers want to see, it is an inevitable trend in the development of social science and technology at present, and it is also an important means to improve the knowledge level of social people.

In addition, packaging automation equipment has also made outstanding contributions to the sustainable development of enterprises. Today, when environmental protection has become a global trend, enterprises are increasingly in need of reducing resource waste and carbon emissions. Automated systems can accurately control each production link and reduce waste. According to a survey, enterprises that use automated packaging systems have reduced energy consumption by an average of 20%.

In general, packaging automation has not only changed the traditional production methods, but also promoted the development of manufacturing industry towards digitalization and intelligence. It has become a key tool for enterprises to improve efficiency, reduce costs and achieve sustainable development. As technology continues to advance, packaging automation will become even more important in the future, bringing more innovation and competitive advantages to companies.

Challenges faced by manual packaging methods

Although manual packaging once played an important role in the past few decades, as the market environment changes, its limitations have become more and more obvious. With the emergence of packaging automation, the time required to package a product is getting longer and longer. The shorter. Today, companies are facing a series of challenges that make manual packaging increasingly uncompetitive.

First of all, high production costs are one of the most significant disadvantages of manual packaging. As mentioned above, the issue of labor costs continues to rise around the world, especially in developed countries. The laws and regulations of developed countries have sufficient protection for people’s rights. Companies cannot force these employees to work overtime, but the factory’s Production and packaging are urgent, and people can only be added continuously to speed up packaging and production, which puts huge financial pressure on the company. Hand packaging requires a large number of workers, and the wages and benefit costs of these workers continue to increase over time. In contrast, packaging automation can significantly reduce these costs by reducing reliance on labor. Some studies show that companies using automated packaging systems can reduce overall operating costs by 20.5% to 30.3%. This cost saving is not only reflected in direct salary expenses, but also includes the reduction of unnecessary costs caused by various problems caused by manual errors.

Secondly, inefficiency is another major problem faced by manual packaging. Manual operations will inevitably lead to speed bottlenecks. No matter how skilled the employees are, their production speed is always limited by physiology and fatigue. Machines can run 24 hours a day, but people cannot. In addition, manual packaging is more prone to errors and inconsistencies, leading to a decrease in production efficiency and fluctuations in product quality. After a person repeats a large number of mechanical behaviors, it will become muscle memory. At this time, if the packaging method is changed, people will be out of control. Due to muscle memory, the previous operation will continue to be repeated, so that you need to keep going back and repeat the steps, which adds a lot of time cost. This inefficient production method cannot meet the modern market’s requirements for efficient production, especially when orders are large and fast delivery is required. In contrast, packaging automation equipment can achieve a faster and more stable packaging process, reduce errors caused by human intervention, and improve the overall efficiency of the production line.

Third, manual packaging lacks flexibility, which is particularly fatal in today’s rapidly changing market environment. But some people see that manual packaging should not lack the most flexibility, right? People can use their own ideas to package products how they want, such as strange-shaped gift boxes, such as flowers. These are indeed very effective methods for small batches, and even the effect of manual packaging of these products is much better. It is better than packaging automation, but imagine that a furniture manufacturer has just designed a new home product. The market response is very enthusiastic and orders are coming in like a snowflake. However, due to manual packaging, workers were asked to go to the production line to make money even before they were fully proficient in packaging new products. The result is self-evident. At this time, companies found that they could not quickly adjust the production line to adapt to this new product. New product packaging needs, all this means that product delivery will be delayed, and may even miss the best sales window in the market. In contrast, if companies adopt a packaging automation system, they can quickly adapt the automation equipment to the packaging needs of new products through simple parameter adjustments, without requiring a lot of retraining and adjustment time. This flexibility enables companies to be more calm in the face of market changes, not only able to respond quickly to customer needs, but also to seize market opportunities.

Finally, environmental impact is also a major issue with manual packaging. Traditional manual packaging often involves a significant waste of resources, especially in terms of material usage and energy consumption. Manual operations can easily lead to overuse and waste of materials, increasing the company’s environmental burden. To give an example in real life, suppose you buy a product in the supermarket and find that the packaging is very complicated, with multiple layers of plastic and paper inside. Most of these packaging are to protect the product during transportation, but in fact many times it is unnecessary. of. Manual packaging often lacks accuracy and can easily lead to material waste. Through precise control of automated packaging systems, this waste can be significantly reduced. According to a survey, companies using packaging automation can reduce material waste by 25.2% and energy consumption by 15.7% on average. This not only helps companies achieve their sustainability goals but also improves their competitiveness in the environmentally friendly market.

All in all, although manual packaging had its value in the past, in today’s market environment, its shortcomings have become more and more obvious. From high costs and inefficiencies to lack of flexibility and environmental impact, manual packaging is gradually being replaced by packaging automation. In order to remain competitive, companies must consider how to address these challenges through automation technology and achieve more efficient and sustainable production methods.

The role of automation and digital transformation

With the continuous advancement of technology, packaging automation not only shows advantages in efficiency and quality, but also opens up broad application prospects in many emerging fields. These characteristics give enterprises more competitiveness and innovation space.

First, packaging automation brings higher traceability. In modern supply chain management, traceability is increasingly valued. Enterprises hope to be able to track the packaging process of each product, from the use of raw materials to the distribution of the final product. This not only helps to improve quality control, but also quickly locate and solve problems when there are problems with the product. Automated packaging systems can record and store a large amount of production data and establish detailed records for each batch of products. These data can help companies better understand the efficiency of each production link and optimize the entire supply chain management.

Second, packaging automation has shown unprecedented flexibility in personalized production. With the personalized trend of consumer demand, companies must be able to quickly adjust production lines to meet customized needs. Automated packaging systems can easily switch from large-scale production to small-batch customized production to meet the specific requirements of different customers. Some high-end consumer product companies are now able to customize the appearance and packaging of products according to customer needs during the packaging process. This flexible production capacity allows companies to meet individual needs while maintaining efficient production.

In addition, packaging automation also improves production safety while reducing human intervention. In manual packaging, workers frequently operate complex equipment and tools, which can easily lead to work-related injuries. The automated system can take on these high-risk tasks, such as carrying heavy objects (the goods themselves) and operating sharp tools (scissors), thereby reducing the possibility of worker injuries. By reducing human intervention, companies can not only improve production efficiency, but also significantly improve workplace safety and reduce the rate of work-related accidents. This is not only beneficial to employees, but also has a positive impact on the company’s social responsibility and brand image.

In addition, packaging automation also improves space utilization by optimizing production line layout. Traditional manual packaging often requires a lot of space to accommodate workers, equipment and storage materials. The automated system can carefully design the production line layout to make the placement of equipment and materials more compact and efficient. This not only saves factory floor space, but also reduces the rental and maintenance costs of some companies’ factory buildings. In addition, the optimized production line layout can also improve logistics mobility, making the transportation of raw materials and finished products smoother, and further improving production efficiency.

Finally, packaging automation also brings more accurate prediction and decision-making capabilities to companies. Through big data analysis of production-related data, automation systems can predict changes in market demand and help companies optimize production plans. For example, some companies adjust the capacity configuration of packaging production lines by analyzing historical sales data and market trends to better cope with seasonal demand or sudden market changes. This forward-looking production capability enables companies to stay proactive in fierce market competition and reduce inventory backlogs or shortages caused by market fluctuations.

Packaging automation is completely changing the way companies operate. It not only significantly improves production efficiency and product quality, but also injects new competitiveness into companies, bringing multiple advantages such as traceability, personalized production, improved safety, optimized space utilization and accurate prediction. These transformative qualities are helping companies to move forward steadily in a complex and changing market and lead the manufacturing industry towards a smarter and more efficient future.

Understanding Automation in Manufacturing

After packaging automation helped improve production efficiency and reduce operating costs, the manufacturing industry has also begun to embrace a wider range of automation applications. Automation is changing not only the packaging process, but the entire production chain, and every link from start to finish is being redefined. For the furniture manufacturing industry, automation technology is creating a revolution, making the originally complex process simpler and more efficient, as if giving wings to the company.

Take a company that focuses on high-end custom furniture as an example. In the past, they relied on manual cutting and assembly. Despite the exquisite craftsmanship, there were inevitably errors, resulting in uneven product quality. But since the introduction of the packaging automation system, the situation has changed greatly. Through robotics, they not only achieved high precision in wood cutting and drilling, but also soared in production efficiency by 35.7%. Like a carefully choreographed dance, these automated packaging systems operate precisely on the production line to ensure that every piece of furniture meets the highest standards.

Artificial intelligence (AI) is like a wise guardian, gradually becoming an indispensable part of furniture manufacturing. Through AI-driven systems, companies can monitor production quality in real time and make adjustments before problems occur. After a large furniture manufacturer introduced an AI system, the product defect rate dropped from 8.2% to 2.7%. This not only reduced rework costs, but also made customers smile, greatly improving customer satisfaction and brand loyalty.

Let’s talk about the Internet of Things (IoT), which is simply the “clairvoyance” on the production line. Through IoT devices, companies can monitor the operation of each production link and perform preventive maintenance through data analysis. A furniture company has greatly reduced equipment downtime by 10.2% and shortened the production cycle by 18.4% through IoT technology. This not only makes the production line as smooth as a cheat, but also significantly improves the market response speed.

And packaging automation equipment also brings companies the “perspective eye” of data analysis. Through these data, companies can accurately identify inefficient links and make targeted optimizations. Data shows that companies that rely on data analysis for optimization have saved an average of 12.7% of operating costs and increased production efficiency by 21.3%. In today’s market environment, this kind of refined management is simply the company’s secret weapon, allowing them to always be one step ahead in the competition.

Not only that, modern furniture manufacturers also use the flexibility of automated packaging systems to explore more customized and personalized production methods. For example, a customized furniture brand uses a packaging automation system to achieve rapid product switching on the production line, so that every customer can get a customized furniture solution. This customization capability is quietly changing the market landscape and bringing customers an unprecedented exclusive experience.

In the future, with the further development of technology, packaging automation will continue to lead the trend of the furniture manufacturing industry. With the help of these technologies, companies will achieve more efficient production control, more accurate resource utilization, and provide customers with more personalized services. This automation revolution is already changing our world, and its story has just begun.

The impact of automation on furniture manufacturing

The impact of Packaging automation in furniture manufacturing has been nothing short of revolutionary. It not only changes the company’s production method, but also gives the company new competitiveness, as if it has injected new vitality into the entire industry.

First, automation brings significant efficiency gains. In the past, manual packaging meant a lot of manual labor and time consumption, but now, automated equipment makes the entire process as precise and efficient as clockwork. Imagine that an advanced automated packaging equipment can complete the packaging task of hundreds of pieces of furniture every minute. This speed is simply ridiculous. Data shows that a leading furniture manufacturing company increased its production efficiency by 28.5% after introducing packaging automation. This means companies can meet market demand faster and get products into the hands of customers even while competitors are still busy adjusting production plans.

In terms of quality, packaging automation also performs favorably. Manual operations are always bound to make mistakes, and the automated system is like a tireless guardian, ensuring that every packaging process is carried out in strict accordance with the set standards. A well-known furniture manufacturer successfully reduced the rework rate by 35.2% through automated packaging systems. This consistency not only improves product quality, but also enhances brand image, because customers always favor products with stable quality.

Let’s talk about costs. Automation is undoubtedly a “sharp tool” for companies to reduce costs. Packaging automation significantly reduces labor costs by reducing dependence on manpower. Moreover, the efficient operation of automated equipment means that resource waste is also significantly reduced. For example, a furniture company reduced operating costs by 17.4% after introducing packaging automation equipment. As efficiency improves, companies recoup their investment in equipment more quickly, and this savings is like equipping the company with a never-ending money printing machine.

Security is also one of the great benefits of automation. In the past, workers were required to carry heavy objects and operate dangerous equipment, which was not only laborious but also full of risks. Now, as automated equipment takes over these high-risk tasks, the rate of workplace injuries has dropped dramatically. Data from one manufacturer show that since the introduction of packaging automation, their workplace injury accident rate has decreased by 42.7%. Not only do companies save on workers’ compensation and insurance expenses, but their employees’ working environment also becomes safer and more comfortable.

The most exciting thing is that packaging automation brings powerful data analysis capabilities to enterprises. Automated equipment is not only working, it is also constantly generating data. This data is like a gold mine waiting to be mined, containing endless business wisdom. Through the analysis of these data, companies can accurately identify bottlenecks in the production process and carry out targeted optimization. By analyzing data provided by automated packaging systems, a furniture manufacturing company successfully increased production efficiency by 19.6% and reduced material waste by 11.3%. Such results not only allow enterprises to take the initiative in competition, but also lay a solid foundation for future development.

Packaging automation has become more than just a tool to increase efficiency and reduce costs. It is bringing unprecedented changes to the furniture manufacturing industry, pushing companies to go further in the market and fly higher.

Implementing Automation in Furniture Manufacturing

The process of implementing packaging automation is like injecting a new soul into furniture manufacturing companies. It is not just a technological upgrade, but also a big step for companies to transition from traditional labor-intensive industries to the next high-tech industry. To successfully implement automation, companies need to carefully plan, execute meticulously, and continuously optimize. Here are a few key steps to help furniture manufacturers smoothly embark on the road of automation.

Identify automation opportunities: Seize the opportunity for transformation

The first step is to identify the links in the production process that can benefit from automation. This is like finding the most in-demand parts for a car, finding those parts that are inefficient, error-prone, or labor-intensive, because not all production processes are suitable for automation, such as quality inspection. There are many machine quality inspections now, but in order to ensure product quality, many companies will send employees to conduct secondary inspections after the machine inspection, because the final parameters of the machine are set by people. If the set values are wrong, the inspection pass of the product and the machine will inevitably be affected accordingly. On the contrary, if the company finds that the product packaging process takes too long and the quality is unstable, this is a good opportunity to introduce automated packaging systems. By analyzing the data, companies can accurately locate bottlenecks and determine which links are most suitable for automation. Of course, it is not necessarily only for the packaging link, but also cutting, veneer and other functions can be automated. The key is to put forward your needs.

Choose the right technology: reject “technology surplus”

Once the links that need to be automated are clear, the next step is to choose the right automation technology. Choosing the right technology is like choosing the most suitable equipment for the company. It must match the specific needs and goals of the company. Currently, there are a variety of packaging automation equipment available on the market, from simple automatic packaging machines to complex robotic systems. Different technologies have their own advantages. Companies need to make wise choices based on their own production scale, product type and budget. If you are a large automobile assembly plant that needs precise installation, the robotic system is the most suitable for you at this time. However, if you just need a simple product packaging, but you want to use the robotic system for packaging, it has to be said that it is an extreme waste of company resources. Don’t think this is alarmist. Many business owners have turned back to the situation of “technology surplus” in pursuit of excessive technology. It is important that technology must be scalable so that the company can continue to benefit from future expansion.

Develop an automation plan: Create your own “TBHR” plan

After choosing the right technology, companies need to develop a detailed automation implementation plan. This step is like developing a battle plan for a tough battle, and every detail must be taken into account. The plan should include Time Table, Budget Management, Human Resource Training, and Risk Management. Companies also need to set clear goals, such as improving production efficiency, reducing operating costs, and improving product quality, and quantify these so that they are within a certain value to meet the goals, so that they can continuously monitor progress and make necessary adjustments during implementation. Successful automation transformation is inseparable from a well-designed and executable plan.

Implementation and testing: E TO E (EXPERIMENT TO EXPLORE)

The premise of this is that a company with multiple production lines can be applied.

The implementation stage is the core of automation transformation. Companies should start with small-scale pilot projects and gradually expand to the entire production line. This process can help companies identify potential problems and make adjustments before full implementation. For example, companies can first introduce automated packaging systems in one production line segment, observe its operating effects and the improvements it brings, and then expand the scope of application. This is why it is suitable for companies that need to add multiple production lines later. If your company only has one production line, please do not use this one and make the above preparations first. The success of the testing phase will lay a solid foundation for full promotion and ensure that the automation system achieves the expected results in actual applications.

Training employees: challenges and safety

Automation is not only about machines, but employee participation is also crucial. Companies need to provide comprehensive training for employees to help them master new technologies and adapt to new production models. At the same time, the most important one is safety training. As I said above, reducing labor costs can definitely reduce the occurrence of work-related injuries, but when medium and large-scale mechanical equipment is added to production, the training of each employee needs to be more rigorous, because once employees are improperly trained and operate incorrectly, and eventually cause work-related injuries, then generally speaking, the injuries are generally not to be underestimated. So training is like giving old employees new “weapons” so that they can still play a role in the automated environment, and they also have to tell them the “Golden Finger Principle”. Through systematic training, employees can not only operate new equipment proficiently, but also participate in the continuous improvement of automation processes. After all, the operation of automation systems is inseparable from human wisdom and experience.

Monitoring and optimization: keep improving and continuously improve

The implementation of automation is not a one-time thing. Enterprises need to continuously monitor the operating status of the system, collect production data, and analyze it. This step is like doing regular maintenance for a car, discovering problems and making timely adjustments to ensure that the automation system always operates in the best condition. Through data analysis, enterprises can identify new optimization opportunities and make corresponding improvements so that the automation system continues to improve as the enterprise develops. In this way, automation not only improves current productivity, but also provides endless possibilities for future innovation and expansion.

Packaging automation is not just a technological upgrade, but also an important step for enterprises to move towards the future manufacturing model. Through careful planning and execution, furniture manufacturers can use the power of automation to achieve comprehensive improvements in production efficiency, product quality and cost control. This not only brings competitive advantages to enterprises, but also lays a solid foundation for them in the ever-changing market.

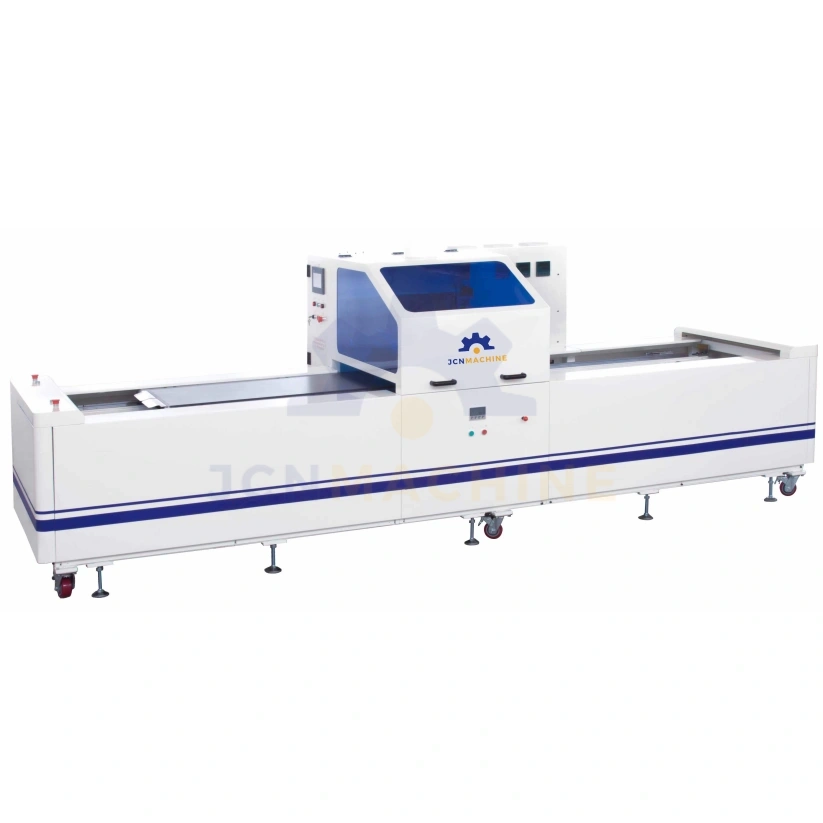

![]()

Looking to the future: Automation trends in furniture manufacturing

With the rapid development of technology, the application of packaging automation in the furniture manufacturing industry is far from reaching its peak. In the next few years, perhaps automation technology will continue to evolve, not only changing the production process, but also redefining the entire industry. Let’s take a look at the automation trends that are already on the way or coming soon. (This paragraph is some estimates or guesses made by the author based on the current market situation and trends. Please forgive me if you think it is wrong)

Deeper application of AI: from intelligence to wisdom

Artificial intelligence (AI) has emerged in the furniture manufacturing industry, but its potential is far from being fully tapped. In the future, AI will no longer be just an auxiliary tool, but a key link in the decision-making chain. In my opinion, in the future, he will be able to independently manage the operation of the machinery, accurately adjust the layout of the automated production line according to the signals of the sensors of the various components of the machinery, and command the production line to produce. This flexibility and foresight will bring huge market advantages to enterprises. He may be able to see things that many people ignore and modify them by himself.

The full popularization of the Internet of Things: Every piece of furniture tells a story

The Internet of Things (IoT) technology has begun to provide unprecedented transparency for the manufacturing industry, and in the future, it will be more deeply embedded in every production link. Through IoT, furniture manufacturers can track the production process of each product in real time, from the source of raw materials, to every step on the production line, and finally to the logistics transportation. A smart label can record this information, so that each piece of furniture has its own “digital archive”. This comprehensive traceability not only helps to improve quality control, but also enhances consumers’ trust. When consumers buy furniture, they only need to scan the label to understand the “background” of this furniture. This transparency will become an important selling point in the future market, and it can to some extent make up for people’s disappointment in not being able to obtain customized products due to mechanized automatic production. (This is inspired by China’s new energy vehicle 4S stores)

Data-driven decision-making: from experience to precision

In the future, data will become one of the most valuable assets in the furniture manufacturing industry. With the widespread application of automation systems, companies will collect massive amounts of data. These data are not just cold numbers, but contain endless business opportunities. By analyzing these data, companies can identify potential problems in the production process and respond quickly, thereby further improving some defects in the production process.

Robotic Process Automation (RPA): Making Machines Smarter

Robotic Process Automation (RPA) is another technology that will change the furniture manufacturing industry. RPA can not only handle repetitive tasks, but also continuously improve its “skills” through learning. In the future manufacturing workshop, robots will no longer be simple labor, but smart “colleagues”. They can autonomously adjust the production rhythm, optimize the workflow, and even participate in complex decision-making. For example, an RPA system can automatically adjust equipment parameters according to the real-time status of the production line to ensure optimal production efficiency. This highly intelligent operation will bring the manufacturing industry into a new era, but as I mentioned earlier, it requires a large enough enterprise scale to be appropriate.

Sustainability and Environmental Protection: The Future of Green Manufacturing

With the increase in environmental awareness, the furniture manufacturing industry will also pay more attention to sustainable development and health. In the future, packaging automation will be closely integrated with environmental protection technology to promote the realization of green manufacturing. For example, companies can accurately control the use of materials through automation systems to reduce waste; through intelligent monitoring, optimize energy consumption and reduce carbon footprint. In addition, recycling and reuse will also become an important part of automated production. Enterprises can accurately manage the reuse of recycled resources through data tracking. This will not only help enterprises fulfill their social responsibilities, but will also become an important factor in attracting consumers with strong environmental awareness.

In general, the future of the furniture manufacturing industry is full of possibilities. Packaging automation will be deeply integrated with advanced technologies such as AI, IoT, and RPA to promote the industry to develop in the direction of intelligence, precision, and greenness. Those companies that are willing to accept challenges and actively embrace changes will occupy a favorable position in future competition and become industry leaders.