INTRODUCTION

The history of the Industrial Revolution has been like a long and exciting marathon, with each leap making the pace of manufacturing more robust. Beginning with the first industrial revolution in the 18th century, we used water and steam power to break the shackles of manual labor and give productivity a powerful boost. Factories then, like freshly wound clocks, began to run at a whole new speed. Immediately following this, the Second Industrial Revolution turned the dream of mass production into a reality through the popularization and application of electricity. Electricity not only provided a constant source of energy for machines, but also realized the goal of “machines making machines,” and factories were like gas pedals, with production lines speeding up again.

In the 20th century, the third industrial revolution, electronic equipment and information technology (IT) is widely used, as if for the industrial manufacturing “intelligent” switch. From then on, production was no longer just a mechanical repetition of labor, but began to pay attention to precision and efficiency. With the support of IT, factory operations have become more precise, and every part can be produced with unprecedented accuracy.

Today, we have entered the era of Industry 4.0, a change that will allow manufacturing to truly enter the “future”. The core of Industry 4.0 lies in intelligent, integrated sensory control systems and highly automated production equipment. These devices are not just simple machines, they can actively think, and even predict and solve problems that may arise during the production process, like production assistants with superpowers. These “smart heroes” not only make production more efficient, but also ensure that every step of the process runs smoothly and is no longer plagued by human error or unexpected failures.

The concept of automation in manufacturing should not just be about improving the efficiency of industrial production and saving operational costs, it is also about changing the way we live our lives. Consumers are now able to easily customize personalized products, such as modern automobiles, which can be chosen by everyone according to different needs, and cars can be equipped with their own colors and even configurations. With the popularization of automation equipment, smart home products such as automatic cleaning robots, smart thermostats have also become more popular, making our lives more convenient and comfortable, imagine if there is no automation equipment for the continuous output of the product, for some of the high-demand products to meet the current stage of the people want to buy that is to have this urgent need.

At the same time, automation also promotes the realization of green production. Modern automation technology has made the production of many products more environmentally friendly, promoting sustainable development.

In addition, automation is reshaping the job market. While some traditional jobs are gradually being replaced, new high-skill jobs are also growing rapidly, providing new career choices and development opportunities for young people, as well as elevating the level of human social development to new heights.

Next we’ll take a look at how – automation equipment – is making an all-encompassing impact on our daily lives by optimizing manufacturing processes and driving social change. Through concrete examples of automation in manufacturing, we will demonstrate the key role these devices play in improving quality of life, promoting green lifestyles, and transforming the job market.

Basic concepts of automated production lines

The concepts here are not a scientific explanation, but just the author’s own understanding of the automation line over the years.

automation in manufacturing is one of the core of modern industry, and automation production line is one of the decisive factors from a professional point of view, automation production line is in fact through the precise control system and a variety of automation equipment, the raw material step by step processing into finished products of complex systems. The key to this is the word “automation”, that is, to minimize human intervention, so that the machine itself to complete most of the work. This not only makes production faster, but also ensures that the quality of each product is consistent and not subject to error due to human error.

Now, let’s take a closer look at some of the main types of automation lines in the manufacturing industry and how they impact our daily lives:

Assembly line automation

It is the most classic form of automated production and is widely used in large-scale manufacturing, such as automotive assembly and electronics manufacturing. Technically, assembly line automation relies on precise time control and spatial layout to achieve a high degree of standardization and continuity in the production process through a series of automated equipment and conveyor systems. The smartphone in your hand, for example, is produced through just such assembly line automation. Each component, from the screen to the battery to the casing, is precisely assembled on the assembly line, ensuring the consistency of quality and functionality of each phone. This production method is like an orderly “relay race”, each machine is completing its own “baton times”, and finally the phone will be handed over to you.

Flexible automated production line

Flexible automation is the ultimate in production flexibility and adaptability, especially for industries that need to adjust their production processes quickly. Flexible automation combines a modular design with advanced control systems that allow the line to quickly switch between product categories without the need for a major overhaul. For example, when you customize a piece of home décor, such as a cabinet in the exact color and size you require, the flexible automation line is right there behind the scenes. The equipment on the production line can adjust its operating parameters according to the needs of different orders, ensuring that each customized product can be manufactured with precision. This flexibility makes personalization possible without sacrificing productivity.

Specialized automated production lines

It is an automated system designed specifically for a specific product or group of similar products, with a high degree of customization and integration. These lines are especially common in the pharmaceutical industry, where the production of drugs requires strict quality control and precise processes. For example, the vitamin tablets you take every day rely on this specialized automated production line behind them. It ensures that each tablet has exactly the same composition and dosage, thus guaranteeing efficacy and safety. The highly optimized configuration of the equipment and the automated controls prevent any human error and ensure the high quality of the product.

Fully automated lines

It represents the highest achievement in automation, realizing a seamless transformation from raw material to finished product through a fully automated process. Fully automated production lines are particularly suitable for industries that require the highest level of process precision, such as semiconductor manufacturing. In such a production environment, any small error can lead to huge losses. For this reason, semiconductor chips are often produced in fully-enclosed dust-free chambers with fully-automated equipment. From material handling to final packaging, the entire process takes place in a highly clean environment to ensure the quality and performance of each chip. This fully automated production method ensures the stable and reliable operation of our daily electronic devices.

Semi-Automated Production Lines

It is a production system that still requires manual operation in certain processes, and is usually used in complex processes that cannot be fully automated. For example, the production of high-end handicrafts, such as hand-woven carpets, relies on the skill of the artisan for the weaving process, but the dyeing and cutting processes can be automated. Semi-automated production lines can effectively combine manual and automated operations, allowing production to retain the finesse of craftsmanship while improving efficiency and consistency.

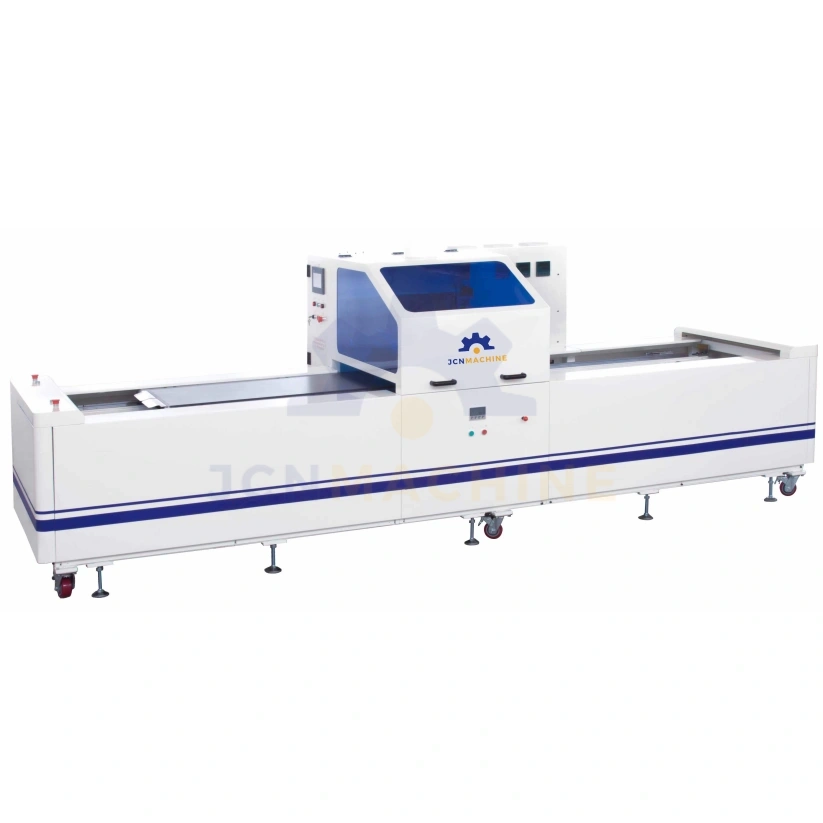

First, the automation control system is the core of the entire production line. It coordinates and manages all aspects of the production process so that each piece of equipment performs the right task at the right time. The system acts as the “brain” of the production line, ensuring that the process runs smoothly through precise instructions. For example, in a production line to manufacture furniture, most of the furniture nowadays use melamine-impregnated paper, through the stainless steel template, high temperature and high pressure pressure pressure pasted to the wood, and then sealing and other processing, automated control system will command the assembly line, in the wood and glue-impregnated paper pressure pasted into a finished product, pushed to the next step, and then the cutter to cut the wood accurately, and finally let the sealing equipment to seal the edge, and ultimately the formation of a complete piece of furniture. a complete and usable furniture module.

Next are advanced sensors and testing equipment, which act as the “eyes” and “ears” of the automated production line. These devices monitor every detail of production in real time, from the input of materials to the output of the finished product, to ensure the quality of the product. For example, the packaging line, when a product needs to be packaged to slide to the corresponding packing position, the sensor will receive information, and then the automated process began to operate, including boxing, gluing package, etc., and ultimately infrared equipment will check whether there is no sealed edges to do a second confirmation, confirmation of the completion of the conveyor belt will be the packaged products directly transported to the next step, but of course, now many of the conditions of the catering super large! Of course, nowadays, many companies have the conditions of food super-large enterprises, will be directly transported to the products of the conveyor belt to the corresponding position of the shelves, which is the next important technology to say.

Automated conveying and sorting systems. This system acts as a “transportation hub” for the production line and is responsible for efficiently transporting materials and semi-finished products, as well as packaged deliveries, to the next process at each stage of production. This automated transportation system is not only completely free of human intervention. For example, Jingdong has a complete automated express delivery equipment, in the packaging is completed, the express box will be affixed to the above list, and then the equipment scanning bar code, followed by the conveyor belt will be transported directly to the corresponding position of the product, this process almost do not need personnel to operate.

These technological advances make the automated production line not just a simple mechanical process, but a highly coordinated and intelligent system. Together, they make the production process more efficient, reliable and adaptable to meet changing market demands. Because of this, more and more manufacturing companies are adopting these advanced automated production technologies to improve their competitiveness.

According to the latest data, by 2025, more than 50% of the world’s manufacturing companies will adopt these advanced automated production lines [Source: Gartner, 2023]. This trend is not only changing the face of the manufacturing industry, but it is also having a profound impact on our daily lives, as more and more products are being manufactured through these intelligent production lines.

Automated production lines: a powerful driving force for change in global manufacturing

Automated production lines are revolutionizing global manufacturing at an alarming rate. This is not only an improvement in technology, but also a far-reaching change that redefines the core concept of manufacturing. From traditional manual operations to modernization and intelligence, automation in manufacturing has not only brought significant improvements in efficiency and significant reductions in costs, but has also completely changed the company’s operating model and market competition. This article explores the widespread impact of automated production lines on manufacturing processes and their potential for future growth.

Basic concepts and significance of automation

First, we need to clarify the basic concepts of automation. Automation in manufacturing refers to the use of highly developed technologies and systems in the manufacturing process to minimize manual intervention, thereby greatly improving production efficiency and product quality. This transformation not only symbolizes technological progress, but also marks the comprehensive transformation of the manufacturing industry from traditional operating models to modernization and intelligence.

The introduction of automated production lines has completely changed the global manufacturing landscape. It not only speeds up production and reduces operating costs, but also prompts companies to make profound adjustments in operating models, technical management, and market response. Today, automation in the manufacturing industry has become an unstoppable trend worldwide, bringing complex and far-reaching impacts.

However, this change also brings huge challenges. Enterprises must adapt quickly at multiple levels such as technology, strategy, management and market response to cope with the multiple challenges and opportunities brought about by automation technology.

Profound changes in business operating models

In traditional manufacturing models, production schedules are usually limited by human resources. The length of workers’ working hours directly affects production efficiency. This dependence leads to low efficiency, especially in industries that require 24-hour continuous production, such as food and beverage, chemical industry, and electronic manufacturing.

The introduction of automated production lines completely changed this situation. By introducing highly automated equipment, companies can break through time constraints and achieve uninterrupted production around the clock. Whether it is robots, CNC machine tools or automatic inspection systems, these automation equipment have demonstrated unparalleled advantages in their respective fields, significantly improving production capacity and market response speed. This model shift not only allows companies to occupy a more favorable position in market competition, but also enables them to more flexibly adjust the production rhythm and seize market opportunities in a timely manner.

However, the efficient operation of automated production lines also brings new challenges. The efficient operation of equipment requires strict maintenance and updates to ensure the continuity of production and the stability of the equipment. Enterprises need to continuously improve their technical management capabilities and establish a rapid response mechanism to deal with equipment failure and production shutdown losses. In addition, with the frequent updating of high-tech equipment, enterprises are facing higher requirements in terms of technical reserves, talent training and management capabilities.

The development and challenges of product diversity

Another significant advantage of automated production lines is their standardized production processes. This approach not only improves production efficiency, but also greatly enhances product consistency. In mass production, automation in manufacturing can produce high-quality standardized products at lower costs to meet the needs of the mass market.

However, with the diversification of consumer needs and the increasing trend of personalization, the standardized characteristics of automated production lines have also exposed their limitations. In the high-end consumer goods market, consumers not only pay attention to the function and quality of products, but also pay more attention to the uniqueness and personalized design of products. To cope with this challenge, companies began to explore the application of flexible automated production lines. Through modular design and flexible manufacturing technology, flexible automated production lines can realize small batches and diversified production models to meet the personalized needs of the market.

At the same time, the rise of smart manufacturing technology has further promoted the flexibility of automated production. By introducing artificial intelligence (AI) and machine learning technology, companies can more accurately respond to consumers’ personalized needs and achieve a higher level of personalized production.

But even in such an era of high automation, the unique value of handicrafts is still difficult to completely replace. In the luxury goods and high-end customization markets, the artistry and uniqueness of hand-made production still occupy an important position. Therefore, in the process of promoting automation, companies must find a balance between standardized production and personalized customization, retain handicraft production lines, and combine automation technology to meet market demand and create unique value.

Changes in the way information is managed and used

Automation in manufacturing not only changes the production process itself, but also revolutionizes the way information is managed and data is utilized. Automated production lines have significantly improved the transparency and controllability of the production process. Enterprises can collect and monitor various data in the production process in real time through the automated system.

This data is crucial for optimizing production processes and improving resource utilization efficiency. Through the analysis of production data, companies can identify bottlenecks and problems in production, further optimize the production process, and improve production efficiency and product quality. In addition, data analysis also helps companies predict changes in market demand, adjust production plans, reduce inventory pressure, and improve market response speed.

But just as every coin has two sides, the widespread application of data also brings data security challenges. As the importance of data in enterprise operations increases, data security management has become an important issue that enterprises must face. If a large amount of data that an automated system relies on is leaked or attacked, it may cause the company to suffer huge business losses and even endanger the company’s survival. Therefore, enterprises need to strengthen data security management and establish a complete data protection mechanism to ensure data security and reliability.

With the development of Internet of Things technology, more and more automation equipment begin to operate online, and the collection and transmission of production data become more complex. Enterprises need to ensure the integrity and security of data through advanced technology and management mechanisms.

The dual impact of environmental protection and resource utilization efficiency

The promotion of Automation in manufacturing has brought significant environmental benefits. The efficient operation of automation equipment not only reduces resource waste, but also improves energy efficiency. This not only reduces the company’s operating costs, but also conforms to the global trend of sustainable development.

However, the manufacturing, use and end-of-life processes of automated equipment also bring new environmental challenges. The production process of automated equipment consumes a lot of resources and energy, and the maintenance and update of the equipment also require a lot of resources. After the equipment’s service life ends, how to carry out environmental protection treatment and resource recycling has become a problem faced by enterprises.

To deal with these challenges, companies need to introduce environmentally friendly technologies into the production process and reduce their impact on the environment through resource recycling and green manufacturing technologies. The concept of circular economy becomes particularly important in this context. Enterprises can support resource recycling and reduce environmental impact through automation technology.

In addition, enterprises also need to strengthen the full life cycle management of equipment. In all aspects of equipment design, manufacturing, use and scrapping, companies should reduce resource consumption and environmental pollution as much as possible to achieve sustainable development goals.

Automation’s broad impact on the future of manufacturing

The impact of Automation in manufacturing on the future of manufacturing is complex and far-reaching. As automation technology continues to advance, the manufacturing industry will further improve production efficiency, product quality and market response speed. In this process, enterprises need to constantly adjust their operating models, technology management and data security strategies to adapt to the new market environment.

However, the promotion of automation technology also brings many challenges. While pursuing efficiency and quality improvement, companies must pay attention to issues such as employee skill improvement, social responsibility fulfillment and environmental protection. The application of automation technology is not only aimed at improving production efficiency and reducing costs, but also needs to consider its impact on wider social and environmental levels.

With the further development of artificial intelligence, Internet of Things and big data technology, automated production lines will become more intelligent and flexible. In the future, the emergence of new technologies such as 5G and quantum computing may further promote the innovation of automated production, making it more forward-looking and competitive. Enterprises need to keep up with the pace of technological development, continuously innovate and optimize production processes to maintain competitive advantages.

In the context of increasingly fierce global competition, only those companies that can make full use of automation technology, respond flexibly to market changes, and pay attention to sustainable development can occupy a favorable position in the future manufacturing industry.

Industries that have basically achieved automation

With the popularization of automation in manufacturing, many industries are no longer what they used to be. Automation technology is like a gust of wind that has swept through various fields and brought about earth-shaking changes in traditional production methods. Let’s take a look at how these industries have been rejuvenated with the help of automation.

1. Textile and clothing industry

Once upon a time, the textile and clothing industry was a stronghold of manual operations, and every stitch and thread had to be sewn out bit by bit by workers. However, after the first industrial revolution, there were actually signs of automation in the textile industry, but it was not completely automated. Until the electronics industry, the textile and clothing industry had actually tended to complete automated production, but at that time it could only tend to mass customized production. With the advancement and development of science and technology, the replacement of automation technology has appeared, and everything has changed. Now, automated sewing machines and cutting systems are not only fast, but also as precise as dancing ballet. Imagine that you just ordered a pair of customized sneakers online, and in a blink of an eye, it has been accurately cut, sewn, and packaged by automated equipment in Adidas’ “Speedfactory” factory, and finally delivered to your door. The whole process is shorter than the time you wait for takeout [Source: Adidas official report, 2023]. Isn’t this speed flying? Automation makes the textile industry more comfortable in dealing with fast fashion trends, as if it can keep up with the trend at any time.

2. Construction and building materials industry

The construction industry has always been regarded as “synonymous with wealth”, but today’s construction sites are no longer the “brick-moving sites” of the past. The intervention of automated equipment is giving this traditional industry new vitality. You may have heard that 3D printing technology is changing the face of the construction industry. Imagine that a high-tech “printer” can “print” an entire wall in a few hours, faster than building a sand sculpture [Source: Internal report of Chinese construction companies, 2023]. Moreover, this automation technology is not only fast, but also extremely reliable, with almost no errors. The future construction industry may become more and more like the scenes in science fiction movies, with construction workers more likely to monitor in front of computers rather than sweating on the construction site.

3. Agriculture and food processing industry

Agriculture may be one of the industries that you least associate with automation, but the reality is that this field has begun to become as intelligent as the future farm. Today’s farmers are like “high-tech farmers”, driving automated tractors and controlling drones to spray pesticides, just like “Transformers” in the farmland. Not to mention the smart irrigation system, which can automatically adjust the amount of watering according to soil moisture, which is more accurate than watering your potted plants at home [Source: U.S. Department of Agriculture, 2023]. These automation technologies not only make farmland more productive, but also reduce waste and labor costs. Agriculture is no longer an industry that relies on the weather, but has become a “smart” industry.

4. Packaging and logistics industry

The packaging and logistics industries, two industries that used to rely on manpower, have now been completely subverted by automation technology. Imagine that in Amazon’s warehouse, instead of human labor busying around the shelves, hundreds of warehouse robots are shuttling around, moving goods as quickly and efficiently as playing a “whack-a-mole” game [Source: Amazon official report, 2023]. These robots not only reduce the chance of error, but also shorten the order processing time beyond belief. Think about those customized packages, which are carefully “dressed” by automated machines, making each package like a gift tailored for you. The moment you open it, it’s like opening a blind box. In China, express delivery in many areas has cancelled human transportation and replaced it with unmanned express delivery vehicles. The express delivery vehicles will drive directly to the nearest express station or even directly to your door.

5. Printing and publishing industry

The printing and publishing industry, once considered a “sunset industry”, has now been rejuvenated with the help of automation technology. From automated typesetting to high-speed printing machines, the whole process is like pressing the “fast forward button”. Imagine that a publisher receives a new order for a best-selling book, and the automated typesetting system is immediately activated. The manuscript is typeset in a few minutes, and the high-speed printing press roars. Within an hour, a brand new book is ready [Source: Global Printing Association, 2023]. This efficiency is simply jaw-dropping. Automation has revitalized the printing and publishing industry, and even made “printing on demand” possible, greatly reducing inventory and waste.

Strategies for optimizing manufacturing processes in automated production lines

In today’s manufacturing era where “speed is king”, automation equipment has become standard for many companies. However, in order to truly gain an advantage in the competition, it is not enough to rely solely on automation. “A good computer needs supporting software in addition to powerful hardware.” Companies also need some practical strategies, that is, to further optimize their automated production lines. This is not only to continuously improve production efficiency and optimize product performance, but also to cope with market changes and maintain competitiveness. But what can make your automated production line even more powerful?

1. Data-driven decision-making

When it comes to optimization, the first thing to mention is data. Data is like a “scout” for automated production lines. They can tell you where to improve and where to improve. Today’s production lines are no longer “mechanical factories” in the traditional sense, but a complex and complete system composed of multiple systems. By collecting and analyzing relevant data from different “systems” in real time, companies can make more accurate decisions. For example, some equipment on a production line may always stop frequently, affecting overall production efficiency. Through data analysis, companies can quickly identify problems and take targeted solutions instead of blindly guessing or blindly adding manpower.

According to Gartner’s research, data-driven production decisions can not only increase the company’s production efficiency by an average of 20%, but also reduce the error rate in production by 25% [Source: Gartner, 2023]. The benefits of data-driven are far more than that. It can also help companies predict future production needs, adjust inventory and production rhythm, and avoid overproduction or material shortages. This is like an online store owner who opened an online store, but he didn’t know what products he should run. Then, through Google trend, etc., he looked for some product trends to see which products he wanted to make had good trends. Based on good data trends, the “seeds of victory” can be planted for the subsequent online store to go smoothly.

2. Flexible manufacturing: adapt to market changes

The market is like the weather, which is changeable. And flexible manufacturing is the “windbreak” for companies to cope with market changes. Flexible manufacturing simply means that you can adjust the industry direction, product production method or size change in the future, leaving enough room for adjustment, which means that the production line can change according to market demand. In the past, once the production line was finalized, it was difficult to make adjustments, as if it was “locked” in a production mode. But now, with the introduction of flexible manufacturing technology, companies can flexibly switch between different products, and even customize production according to the personalized needs of customers.

Take the COVID-19 as an example. After the COVID-19 cases began to appear on a large scale in China, the market demand for medical masks increased greatly, but there were only a few manufacturers producing masks, and they lacked the necessary materials. At this time, many Chinese companies have such foresight, using the machinery in their hands to flexibly adjust to become a mask manufacturing machine, formally flexible manufacturing, to solve China’s urgent needs.

This flexibility makes companies more competitive in dealing with market fluctuations, just like a captain who can keep the rudder steady in a storm. It not only helps companies seize market opportunities, but also makes production lines more efficient and economical.

3. Predictive maintenance: Prevent problems before they happen

Nothing is more troublesome than a production line shutdown. And predictive maintenance is the “savior” designed to solve this problem. The traditional equipment maintenance method is a bit like “treating the head when you have a headache and the foot when you have a foot pain”. It is often necessary to repair the equipment only when it breaks down, which often leads to production interruptions and losses. Predictive maintenance can detect the problem in daily equipment maintenance before the problem occurs, and finally “prescribe the right medicine”. It is like a person going to the hospital for regular check-ups every year, so that some difficult-to-detect symptoms can be strangled in the cradle before they get worse.

Predictive maintenance can also help companies arrange maintenance time reasonably and avoid equipment maintenance during peak production periods, thereby minimizing the impact on production plans. This “pre-emptive” maintenance method allows companies to deal with equipment failures in an orderly manner instead of being in a hurry.

4. Intelligent supply chain management

Optimizing automated production lines cannot ignore the intelligent management of the supply chain. The supply chain is like the “lifeline” of the production line. Without a stable supply chain, no matter how advanced the production line is, it will be useless. Intelligent supply chain management systems can not only monitor the use of raw materials in real time, but also automatically adjust supply plans according to production needs to ensure that production lines will not stop at any time due to lack of raw materials.

For example, some manufacturing companies have introduced intelligent warehousing systems that can automatically identify the inventory level of raw materials. Each time a call is made from the warehouse, the system will record it and trigger a warning prompt when the inventory is close to the preset minimum value, telling managers which raw materials need to be purchased, and even adjusting the priority of orders according to the supplier’s delivery cycle. This intelligent supply chain management reduces inventory backlogs and capital occupation, helping companies to move forward steadily in market fluctuations.

5. Optimization of human-machine collaboration

The degree of automation is getting higher and higher, but human-machine collaboration is still an indispensable part of modern manufacturing. There are many reasons for this situation, most of which are due to some force majeure. Optimizing human-machine collaboration can not only improve production efficiency, but also reduce the labor intensity of employees. Reducing the labor intensity of employees means that companies can reduce some of their labor costs. On modern production lines, machines and human employees each play different roles, and the collaboration between them is like a carefully choreographed “dance”, and every step must be seamless. This is why many companies in the market still use semi-automatic production lines.

Through reasonable task allocation, let the machine handle highly repetitive and labor-intensive tasks, and let employees be responsible for processes that require flexible thinking and judgment. This can not only give full play to the strengths of the machine, but also allow employees to be creative. For example, on the automobile assembly line, robots are responsible for precise installation or welding and other complex or dangerous work, while workers focus on the final inspection and adjustment, and pay attention to confirmation according to the checklist provided by the company to ensure that each car meets strict quality standards.

Optimizing human-machine collaboration can also help improve the safety of the working environment. As mentioned above, welding work has certain safety hazards. By letting machines take on high-risk work, workers can stay away from dangerous areas, thereby reducing the incidence of work-related injuries. This is also one of the reasonable measures for companies to reduce operational risks. This “division of labor and cooperation” model not only improves production efficiency, but also saves companies a lot of safety management costs.

In general, the optimization of automated production lines is not achieved overnight, but a process of continuous improvement. By implementing these strategies, companies can give full play to the potential of automated production lines and maintain a leading position in a highly competitive market.

Challenges and countermeasures in the implementation of automated production lines

Although automation in manufacturing brings great potential, companies may face some deep challenges in its implementation. These challenges not only involve technology and capital, but also involve more complex strategic and philosophical issues. The following are five deeply thought-out views that explore the complexity in the implementation of automated production lines.

1. Integration of technology and culture: from “technology first” to “technology for people”

When promoting automated production lines, companies often regard technology as an omnipotent “savior”, believing that as long as they have advanced equipment and systems, all problems can be solved. However, this “technology first” thinking may overlook a key issue: whether technology can truly be integrated into the culture of the company and become a natural extension of employees’ daily work. Automation should not be a cold mechanical operation, but an organic part of corporate culture, giving employees more sense of value and belonging.

The real challenge lies in how to deeply integrate high technology with corporate culture. If companies blindly pursue technological upgrades and ignore employees’ feelings and adaptability, it may eventually backfire. The introduction of automation technology must take into account employees’ work experience and cultural identity. Otherwise, no matter how advanced the technology is, it will be difficult to play its due role. For example, in some traditional manufacturing companies, employees may be accustomed to the manual operation skills accumulated over many years. Suddenly, they will adapt to the fully automated working environment, which will inevitably cause resistance and difficulty in adaptation. At this time, companies need to do more than just technical training. They should also build culture to make employees understand and accept the changes brought about by automation, and then regard automation as a means to improve work quality and creativity.

2. The paradox of data autonomy and integration: the dispute over the “sovereignty” of data

In modern manufacturing, data is no longer just a by-product of the production process, but a core resource of corporate strategy. With the popularization of automated production lines, companies generate massive amounts of data every day, which can be used to optimize production processes, improve product quality, and even predict market demand. However, it is the value of this data that has caused companies to fall into a complex paradox between data autonomy and data integration.

In the data-driven era, companies often need to rely on technical platforms provided by external suppliers to process and analyze data. These platforms can provide powerful computing power and complex algorithms to help companies transform data into useful information and decision-making basis. However, this reliance also means that companies have given up control over their data to a certain extent, and may even let the “sovereignty” of data fall into the hands of others.

Imagine that your company works with a large technology company and uses their cloud platform to store and process all production data. Over time, you will find that although this data helps you optimize production, you have less and less say in how the data is processed and where it is stored. Worse, once you decide to change suppliers, migrating this data may become extremely complicated and even face the risk of losing data.

This situation forces companies to rethink: How much “sovereignty” do we have over data? Will this data dependence weaken the competitiveness of the company or even put the company in a passive position at a critical moment? Going further, if data becomes an “asset” of external suppliers rather than the company’s own resources, to what extent can the company make strategic decisions independently?

To solve this paradox, companies need to adopt a more cautious and forward-looking strategy. First of all, companies should maintain the initiative in data management and avoid over-reliance on a single external platform. For example, a multi-level data management system can be built through internal development or cooperation with multiple suppliers, so that even if a supplier has problems, the company can still maintain control over the data.

Secondly, companies need to strengthen the legal protection of data to ensure that the ownership and use rights of data are clearly defined when cooperating with external suppliers to avoid data “outflow” or abuse. By signing a detailed data protection agreement, companies can gain more protection for their data “sovereignty”.

Finally, companies should also invest in independent data analysis capabilities and gradually reduce their dependence on external technology platforms. This is not only to protect data security, but also to maintain strategic flexibility and autonomy in future competition. Only when the data is truly in the hands of the company itself can the company gain a firm foothold in the wave of automation and make more informed decisions.

3. The ethical dilemma of automation: the balance between efficiency and humanity

Automated production lines have brought about an increase in production efficiency, but it has also raised a profound ethical issue: Will efficiency supremacy weaken the company’s humanistic care? When automated equipment replaces a large number of manual labor, how do companies deal with the resulting social responsibilities? Employees’ re-employment, career transformation, and mental health issues all require companies to give full consideration when promoting automation.

When implementing automation, enterprises must have a more macro perspective, combining technological progress with humanistic care. The goal of automation should not only be to reduce labor costs, but how to create new employment opportunities and social value while improving efficiency. Enterprises should assume social responsibility and help employees adapt to the new technological environment through education and training, career transformation support, etc.

4. The tension between automation and innovation: the confrontation between standardization and flexibility

A huge advantage of automated production lines is that they can achieve standardized production, so that every product is like a “copy”, ensuring consistent quality and efficiency. But the problem is that standardization and innovation are often two incompatible concepts. Over-reliance on standardized automated production lines may cause companies to “go too far” on the technological path and lose the ability to flexibly respond to market changes and innovations.

Imagine that you own a factory that produces smartphones, and the automated production line makes the manufacturing of each mobile phone extremely precise, with almost zero error. But the market changes often faster than you expect, and consumers’ demand for mobile phone functions and designs may change dramatically in just a few months. If your production line is too standardized, once a new design or technology needs to be introduced, adjusting the production line may become very complicated and expensive.

In this case, the enterprise is caught in a dilemma: should it adhere to standardization to maintain production efficiency and product consistency? Or should it sacrifice some of the advantages of standardization and give the production line more flexibility so as to quickly adapt to market changes and innovation needs?

In order to break this tension, enterprises can adopt a “modular” approach. For example, the production line is divided into standardized modules and flexible modules. The former is responsible for those processes with extremely high standardization requirements, while the latter leaves room for innovation and change. In this way, the enterprise can not only maintain the advantages of standardization, but also quickly adjust the production line when market demand changes to achieve new innovations. This strategy of “coexistence of standardization and flexibility” allows enterprises to maintain sufficient adaptability in the fierce market competition.

5. Uncertainty in the future: the “double-edged sword” of automation and strategic balance

The advancement of automation is undoubtedly the future trend of the manufacturing industry, but this “double-edged sword” brings not only a bright future, but also the uncertainty that comes with it. This uncertainty stems from the rapid development of technology and the ever-changing market demand, which requires enterprises to face some deep-seated strategic dilemmas when implementing automation strategies.

Imagine that your company has invested heavily in building a highly automated production line, which makes your products popular in the market and takes advantage of cost and efficiency. However, as market demand changes, consumers begin to prefer products with humanized design and handmade elements. This trend makes the originally impeccable automation strategy seem a bit “overly rational” and may even weaken the market appeal of the product.

At this time, you may face such a strategic choice: should you continue to deepen automation and pursue higher efficiency and lower costs? Or adjust the strategy, retain a certain degree of manual manufacturing capabilities, or explore new paths for semi-automated and customized production? This choice is not only related to the short-term interests of the company, but also affects the long-term development direction.

In the face of such uncertainty, companies need a “flexible strategy” that neither relies too much on automation nor completely rejects technological progress. An effective strategy is to adopt a “diversified” manufacturing model, while ensuring mass production, leaving enough space for customized and handmade products. For example, some high-end brands retain handmade customized product lines on the basis of mass production to meet the needs of specific markets. This flexible strategic layout can not only enable enterprises to gain an advantage in the wave of automation, but also quickly adjust product strategies and maintain competitiveness when the market changes.

Ultimately, automation is not a “one-size-fits-all” solution, but a complex strategy that needs to be balanced with traditional processes, market demand and corporate culture. In the process of promoting automation, enterprises must always remain sensitive to market and technological changes and flexibly adjust strategies to cope with future uncertainties.

Conclusion

Automation in manufacturing has completely changed the face of manufacturing. Automated production lines are not only a tool to improve production efficiency, but also a catalyst that promotes the development of the entire industry and society to a higher level. By reducing manual intervention, automated production lines significantly improve production efficiency and product quality, but its impact goes far beyond that.

This technological change has changed the company’s operating model and made the production process more flexible and efficient. It brings more accurate market response and helps companies reduce costs. However, this also requires us to face new human resources challenges, with workers’ roles and skill requirements changing.

In supply chain management, automation technology makes the use and management of data more complex, requiring enterprises to be more prepared in terms of security and privacy. At the same time, although automation equipment performs well in terms of environmental protection and resource utilization, their manufacturing and maintenance also bring certain environmental pressures.

In short, automation in manufacturing brings significant advantages to the manufacturing industry, but it also comes with new challenges. In the future, with the further development of technology, automated production lines will continue to promote the progress of the industry and improve society’s productivity and quality of life.